Quality Solutions

Defect-free products. Expert-Level Service. Quality Guaranteed.

thyssenkrupp Supply Chain Services understands that quality control is critical to a company’s reputation, competitiveness, and operating costs. We’ve worked with manufacturers since 1968 offering a comprehensive set of quality services that include containment, sorting, inspection, rework, quality control engineering, and nondestructive testing

Services

Returns Logistics

Product Integrity & Conformity

Inspection, Sorting, & Rework

Proactive part inspection

Part sorting & verification

Part rework/repair and certification

Dimensional inspections

Yard campaign management

Data analysis & reporting

Process Auditing and Risk Analysis

Advanced Product Quality Planning (APQP)

Failure Mode and Effect Analysis (FMEA)

Production Part Approval Process (PPAP)

Customer Representation/Plant Liaison

Process Flow Diagrams (PFD)

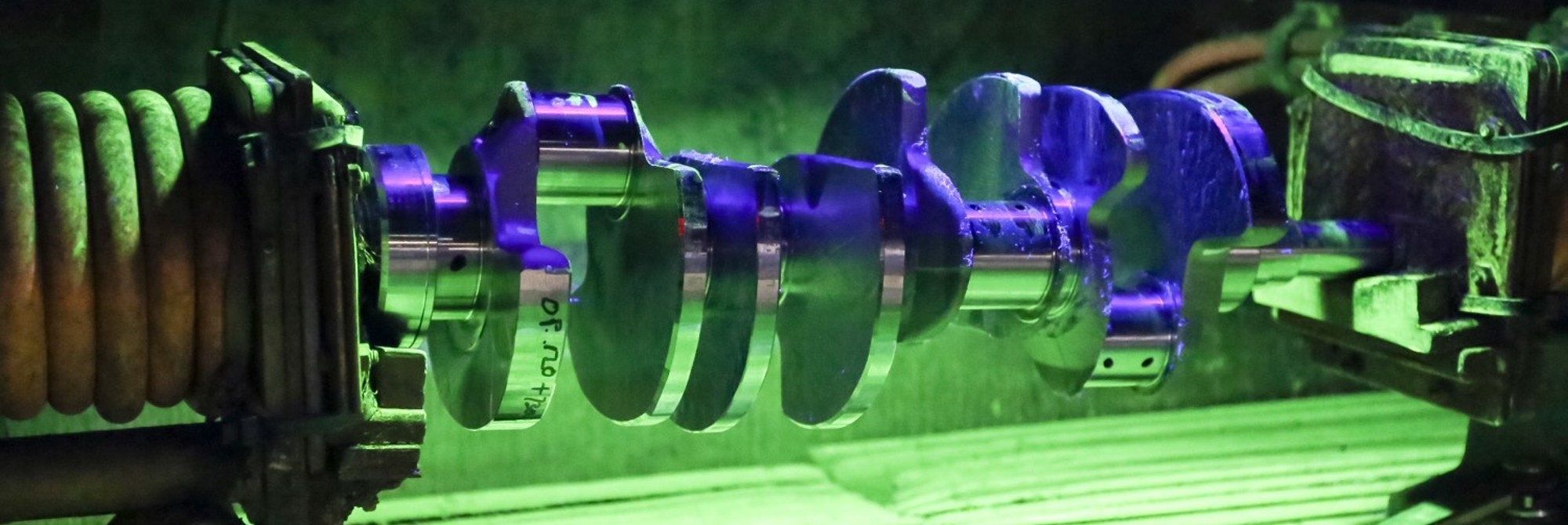

Field NDT Services:

Magnetic Particle Testing (MT)

Liquid Penetrant Testing (PT)

Visual Testing (VT)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Phase Array Ultrasonic (PAUT)

Eddy Current Testing

Magnetic Lift-Off (MLO)

Infrared Inspections

Borescope Inspections

Positive Material Identification (PMI)

Certified Welding Inspector (CWI)

Ground Penetrating Radar (GPR)

Class A Inspections

Metal Finishing

Dent Repair

When you need us there fast, thyssenkrupp Supply Chain Services responds with a professional team that can flex to your requirements. Our engineering team helps you evaluate and improve your quality control practices and conducts effective root cause and corrective action analysis. Serving the automotive, medical device, white goods, heavy manufacturing, and renewable energy industries. Yes, we do that!